As of 2012, the size of the Indian ceramic tiles industry was nearly 172 billion INR and stood on the third position in terms of global production. It also accounted for around 6% of the total world production during the same year.

Top 10 Manufacturing Countries (2013)

| Country | 2013 (Sq. m Mill.) | % on 2013 World Production |

| China | 5700 | 47.8 |

| Brazil | 871 | 7.3 |

| India | 750 | 6.3 |

| Iran | 500 | 4.2 |

| Spain | 420 | 3.5 |

| Indonesia | 390 | 3.3 |

| Italy | 363 | 3.0 |

| Turkey | 340 | 2.9 |

| Vietnam | 300 | 2.5 |

| Mexico | 228 | 1.9 |

In the last few years, the industry performed well with an annual growth rate of around 14%. The organized fraction contributes to almost 50% of the industry, while the top-notch manufacturers across India are known to capture 75% of the organized segment.

- Several small- and medium-size tile manufacturing units operate across the country under unorganized segment with most tile factories being localized to the Indian state of Gujarat.

Geographic Distribution of Ceramic Tile Industry in India:

Several Breakthroughs in the Indian Tile Industry:

- Incorporation of Nanotechnology: This can be considered a major landmark as it helped in increasing the strength and shelf life of tiles, and also made them dirt and bacteria resistant. These in turn enhanced its popularity in places that are required to be highly hygienic, such as research laboratories, food processing facilities and hospitals.

- Introduction of Eco-Friendly Tiles: With the growing environmental awareness among consumers, the use of eco-friendly tiles is increasing with each passing year. Eco-friendly tiles are manufactured using natural and renewable resources, and hence can be recycled.

- Designer Tiles and 3-D Tiles: Tiles are continually gaining popularity as a prominent stuff for interior decoration, especially after the introduction of designer tiles into the market. With numerous designs, patterns, finishes and colors; tiles can be conveniently chosen to match with the interiors. Whether it is about a bedroom or living room, tiles these days are available in an array of designs, with which you cannot just boost the décor, but easily make a style statement. 3-D tiles, a relatively latest addition to the range, also serve the same purpose in a more refined way.

- Drift towards Vitrified Tiles: Vitrified tiles segment has witnessed tremendous growth in the last 5 years with actually occupying nearly 50% of the ceramic tile market. This growth can be attributed to high durability and low-maintenance characteristics of the same.

Current Status & Future Prospects:

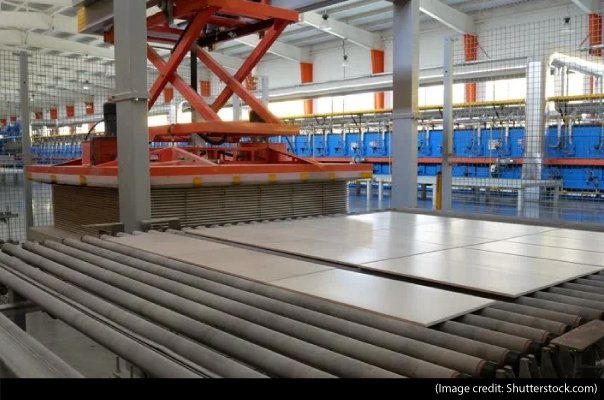

With a steady growth rate, Indian tile industry has marked a prominent position in the global tile manufacturing sector. However, the industry is required to be even more organized with the introduction of state-of-the-art facilities for processing, packaging and shipment to meet the global standards. Indian tile manufacturers are also required to become more professional and customer centric to compete in the global market.

To survive and grow in this highly competitive global market, tile processing units in India should be transformed into relatively larger units that are driven by the philosophy of economies of scale. This would help the tile manufacturers in India to significantly reduce the manufacturing cost. Better and advanced infrastructure can further catalyze this growth with a certain level of sustenance and consistency.

Freight, gas and uninterrupted power supply are other crucial factors that need consideration. Availability of these with reasonable rates can definitely bring down the production cost and contribute to the growth of the Indian tile sector.