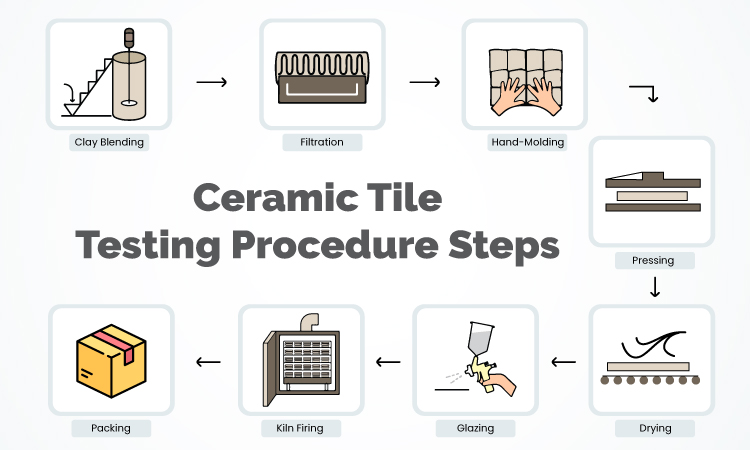

Nowadays, the use of ceramic tiles has increased in various residential and commercial construction projects. Ceramic tiles are manmade but emerge as a superb alternative to expensive natural stone. People who are not aware of the performance of ceramic tile products can evaluate the ability or strength of a tile through a 7-step ceramic tile testing procedure. Before you start testing ceramic tiles, it is vital to know how ceramic tiles are produced at a tile manufacturing unit. The process of ceramic tile production starts with clay preparation. There are lots of steps involved in the process of tile production. The prime stage of the process include:

• Clay preparation by dry grinding or wet milling

• Molding of tile by extrusion or dry pressing

• Ceramic tile glaze preparation

• Decoration, glazing, and drying of the tile

• Kiln firing of ceramic tiles

• Tile classification and packing

Ceramic Tile Testing Procedure Steps

• Green shrinkage – It is related to the measurement of an oven-dried tile. It shows the amount of shrinkage after drying.

• Fired shrinkage – It is concerned with the measurement of the tile’s length after firing. It shows the amount of shrinkage of ceramic tile after firing.

• Porosity – During this testing procedure, the sample tile product is soaked in water for 2 hours. Then, record the weight of the tile. It is done to know the amount of void in the solid.

• Apparent Porosity – Next in the process is apparent porosity which is the ratio of the volume of the entire solid to open pore spaces. Here, three types of weight matter the most: Dry weight, saturated weight, and weight before the sample is drenched in water.

• Linear Shrinkage – This step of the process is about pressing tiles in a rotary disc. Linear shrinkage is related to the percentage of fired and dried shrinkage.

• Compressive Strength – The sixth step in the testing procedure is the test of compressive strength with the help of a Tensometric machine. It shows the ability of the sample to perform under compressive force and loading conditions. It is also associated with the recording of failure when the sample gets loaded.

• Bulk density – The last, but not the least, step in the process includes the measurement of bulk density of the ceramic tile stone using the outcome of the test of apparent porosity.

When any ceramic tile stone gets through these tests, it is declared fit to use. Ceramic tile testing is done to make the most out of the tite product. When you analyze the test report of ceramic tile testing, you find a description of the tiles along with other details like average and normal water absorption ability and bulk density of every tile product.